Asphalt plants play a vital role in our transportation infrastructure, covering approximately 94% of the 2.8 million miles of paved roads in the US and demanding about 420 million tons of asphalt annually.

The unforgiving conditions of asphalt plants can take a toll on equipment, leading to premature failures. This was evident at an Atlanta, GA asphalt plant, where the OEM-designed pulley wore out prematurely, causing tracking issues in the conveying process. Mistracking not only jeapordizes the pulley, but also risks belt edge damage, setting the stage for overall system failure.

Addressing the root cause, the poorly designed OEM pulley, compounded by product build-up stress, results in constant downtime and pulley change-outs.

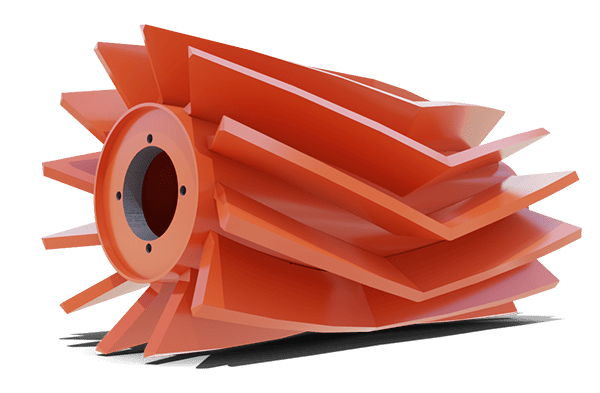

Fortunately, D&D offers a simple yet effective solution—the Capless Chevron Wing Pulleys. With ¾” thick flights and a unique design, these pulleys reduce build-up, enabling easy material filtration and preventing belt mistracking. This not only extends the pulley’s service life, but also minimizes unnecessary wear on the belt, providing a reliable solution to the challenges faced by asphalt plants.

For reduced downtime and increased wear life, the answer is simple—D&D.